Eco-Friendly Innovation

Zero carbon emissions, reducing ~400 Tonnes of carbon per annum

Zero carbon emissions, reducing ~400 Tonnes of carbon per annum

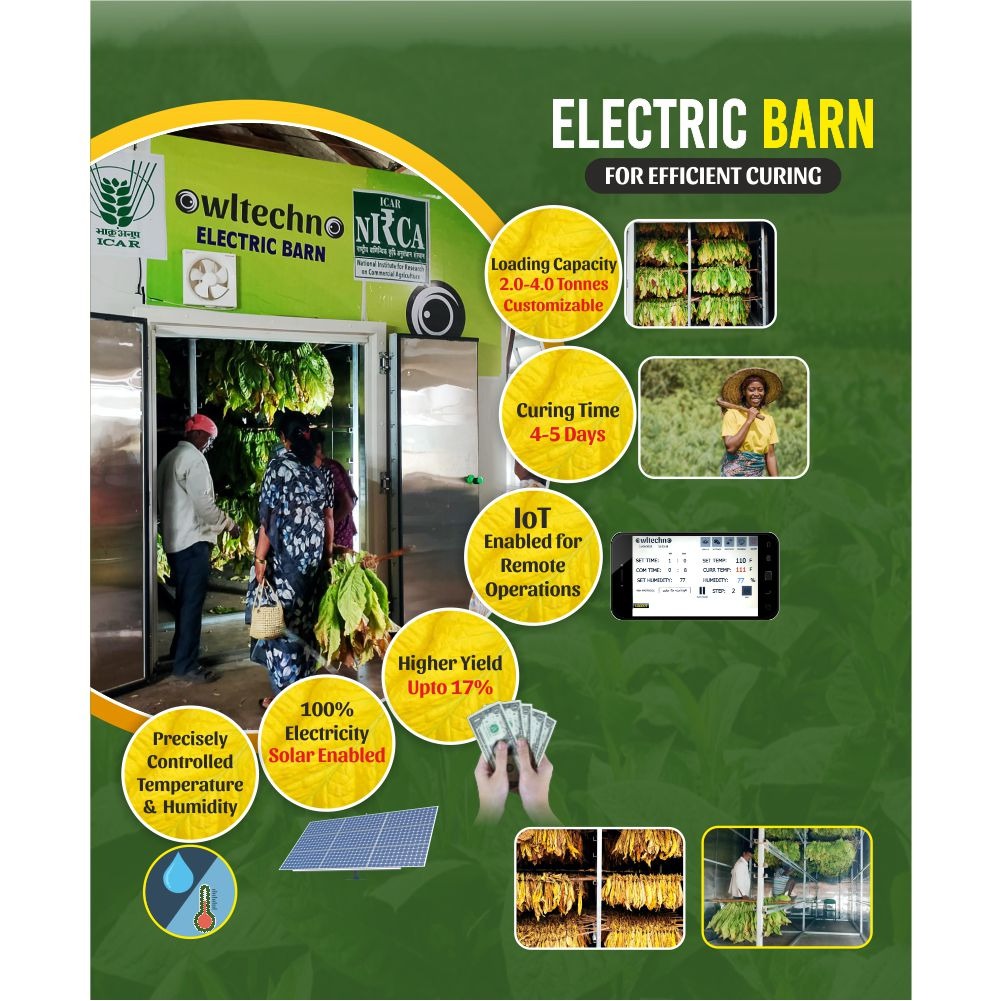

Monitor and Control via mobile for Temperature & Humidity

Prevents the use of 30 Lakh Tonnes of wood per year

Runs on both Electricity/Solar energy

Eliminates Fire Accidents

The heat pump based electric barn prototype designed for FCV tobacco curing by Owl Techno, Hyderabad was evaluated and standardized at ICAR NIRCA, Rajahmundry. It is working efficiently and meets the technical and scientific requirements.

The results of the three parameters tested in samples of FCV tobacco leaf cured in the AEHP barn are within the optimum range and comparable with samples from the standard barn.

Comparison of Traditional Barn vs OWL Techno Electric Barn

| Feature | Traditional Barn | OWL Techno Electric Barn |

|---|---|---|

| Yearly Maintenance | INR 30,000 | INR 2,500 |

| Leaf Loaded | ~3 Tons | ~3 Tons |

| Wood Intake | 1.5 Tons (~INR 7,500) | 0 |

| Manpower for curing (7-8 days) | INR 6,400 | 0 |

| Electricity | 20 Units → INR 140 | 500 Units → INR 3,500 |

| # of days for curing | 7-8 days | 4 days |

| Total Running Cost per Batch | INR 14,040 | INR 3,500 |

| Savings Per Batch | - | INR 10,540 |

| # of Batches per Year | 12 | 16 |

| Savings Per Year | - | INR 1,47,560 |

| Yield % | 15% | 17-18% |

| Other Ingredients Drying | No ❌ | Yes ✅ |

| All Year Revenue Generation | No ❌ | Yes ✅ |

| Return on Investment | Low | High |

India is the 2nd largest country in tobacco farming in the world and One of the major revenue (12000cr per annum) generated crop in the country, High quality of the leaf generates High Revenues, The curing process is the key element to keep the leafs in good quality